Your engine mounts might not be something you think about often, but they play a critical role in keeping your vehicle running smoothly. These mounts secure the engine to the chassis and absorb the vibrations created while the engine is running. When they wear out or fail, you might begin to notice unusual vibrations, noises, and even handling changes while driving.

Understanding how engine mounts work and the signs of failure can help you address problems early and avoid more expensive repairs.

What Engine Mounts Do

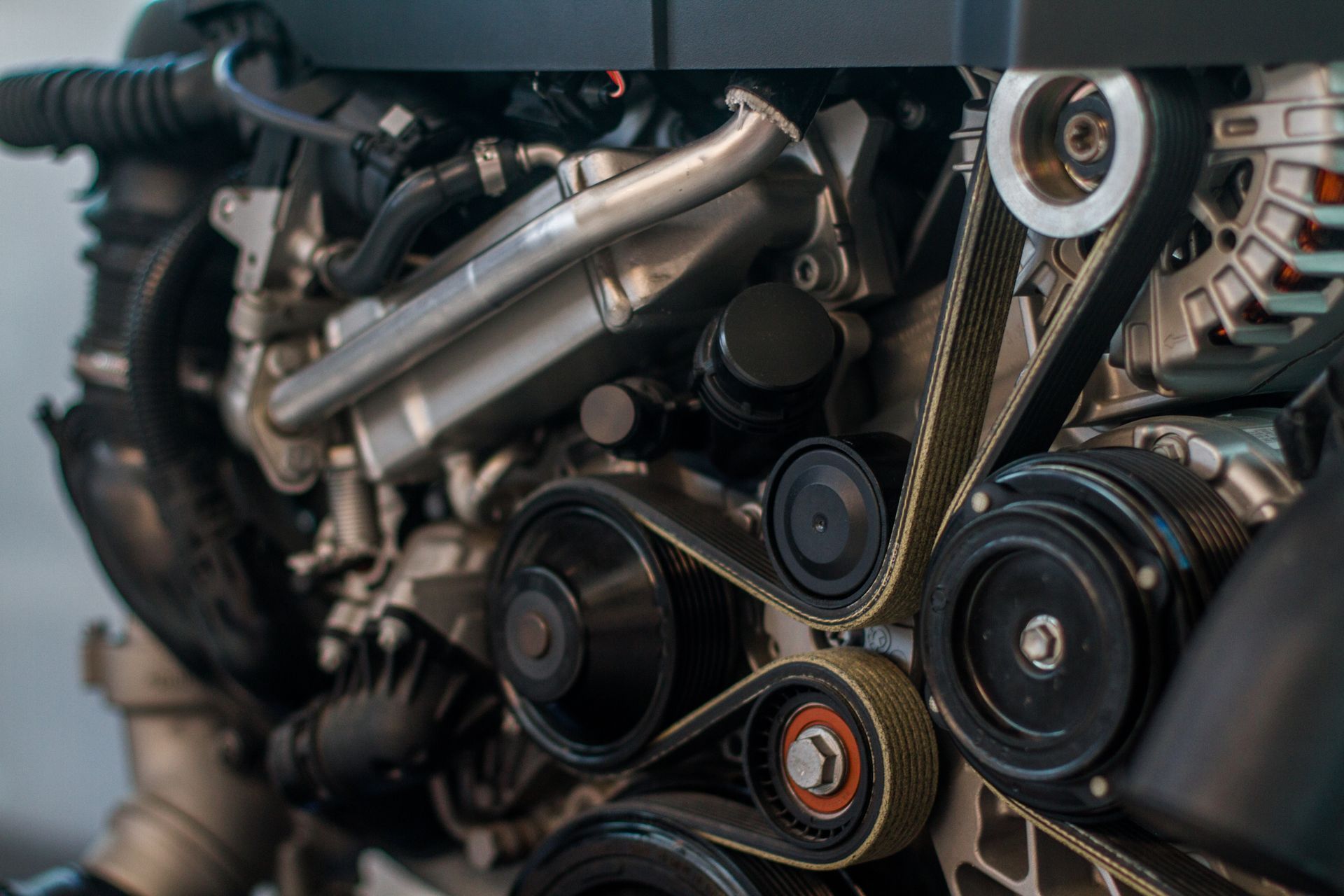

Engine mounts serve two main purposes: securing the engine in place and isolating the cabin from engine vibrations. Most modern mounts are made from a combination of metal and rubber. The metal provides strength and stability, while the rubber absorbs and dampens vibrations before they reach the cabin.

Some vehicles even use hydraulic or electronically controlled mounts that adjust to driving conditions, providing better vibration control and comfort.

How Engine Mounts Wear Out

Over time, heat, engine movement, and exposure to fluids can weaken the rubber or damage the mount’s structure. Hydraulic mounts can also develop leaks that reduce their effectiveness.

Aggressive driving, frequent towing, or repeated hard acceleration can place extra strain on mounts, causing them to wear out faster.

Symptoms of a Bad Engine Mount

One of the first things you may notice with a failing engine mount is an increase in vibration. This vibration may be most noticeable when idling in gear or when accelerating. Without proper support and cushioning, the engine’s natural movement is transferred directly to the vehicle’s frame and cabin.

Other common signs include:

- Clunking or banging noises when accelerating, braking, or shifting gears.

- The engine appears to move excessively when the hood is open.

- A rougher ride or increased cabin noise.

Why Vibration Gets Worse Over Time

When one mount begins to fail, the others take on more stress, which can cause them to wear out more quickly. This creates a chain reaction that can lead to more severe vibrations and even damage to other components, such as exhaust connections, wiring, or hoses.

If ignored, severe mount failure can allow the engine to shift enough to affect alignment between the engine and transmission, leading to drivability problems and possible drivetrain damage.

Diagnosing the Problem

A professional inspection is the best way to confirm whether vibrations are coming from worn engine mounts. Technicians will visually inspect each mount for cracks, splits, or leaks, and may gently move the engine to check for excessive play.

It’s important to rule out other causes of vibration, such as misfiring cylinders, unbalanced wheels, or drivetrain issues. Once confirmed, replacing the faulty mount usually restores smooth operation.

Why You Shouldn’t Delay Replacement

Driving with bad engine mounts can cause more than just discomfort. The increased movement can strain other engine components, shorten the lifespan of exhaust and cooling system parts, and in severe cases, cause safety issues.

Replacing mounts as soon as they fail helps maintain proper engine alignment, protects surrounding parts, and keeps your vehicle comfortable to drive.

Engine Mount Service at Wrench Junkies in Lilburn, GA

If you’ve noticed increased vibration, unusual noises, or excessive engine movement, your engine mounts may be to blame. At Wrench Junkies in Lilburn, GA, we can inspect your mounts, confirm the cause, and replace any that are worn or damaged.

Schedule your inspection today and get back to enjoying a smoother, quieter ride.